If your facility runs on orange single-balloon tread casters, you’re not alone—but you’re likely paying far more than you think. The sticker price might look appealing, but the real story is told in downtime, maintenance, and replacements. It’s time to look beyond the upfront cost and evaluate the total cost of ownership (TCO)—where the Caster Concepts 57 Series swivel caster with maintenance-free sealed precision ball bearings proves itself as the long-term champion.

Orange casters—common in many automotive assembly operations—have long been viewed as the go-to choice due to their low initial price point. But beneath that budget-friendly facade lurks a system riddled with inefficiencies.

These orange balloon tread casters simply aren’t engineered for the real-world rigors of assembly line performance. And while they may be inexpensive up front, every failure chips away at your profit margins and productivity.

Common issues with low-cost casters:

In automotive assembly, every cart movement matters. Whether delivering subassemblies, moving tools, or repositioning parts, your cart’s casters must operate flawlessly—and predictably—under load.

When a caster begins to fail, it doesn’t just squeak and wobble. It slows operations, increases push force and operator fatigue, and risks damaging equipment and injuring workers.

Here’s the real-world breakdown:

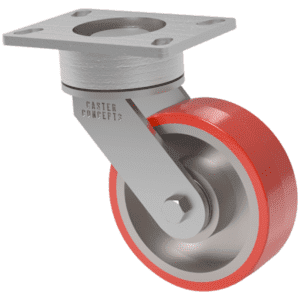

57 Series Swivel Caster with TWERGO Wheel

Let’s say a cart is used to move components 50 yards around a corner, 8 times a day, 5 days a week, 50 weeks a year. That’s 10,000 load-bearing cornering cycles per year.

This isn’t hypothetical. It’s what our testing and field data reveal—time and time again.

The 57 Series caster is a maintenance-free, high-performance caster engineered for environments where durability and reliability aren’t optional—they’re critical. It isn’t just a better caster—it’s an entirely different level of engineering. By eliminating the need for manual maintenance and dramatically extending service life, the 57 Series cuts operational costs while boosting uptime and safety.

Key Features:

Lab-Tested Superiority: When subjected to rigorous in-house testing, the 57 Series outperformed its orange competitor in every key metric:

| Test Criteria | Orange Caster (New) | 57 Series (After 1,000 Cycles) |

| Swivel Slop | Noticeable | Less than Orange (New) |

| Lubrication | Required | Maintenance-Free |

| Load Bearing Cycle Durability | <5,000 cycles | >10,000 cycles |

| Precision Retention | Rapid decline | High tolerance maintained |

This means: |2x – 3x longer between replacements | No unscheduled maintenance | No safety risks from degraded performance.

Real-World Load Simulation

If the orange caster fails at ~5,000 cycles, your team swaps casters twice a year per cart. Add in:

Now scale that across hundreds of carts—and the costs multiply exponentially. |

In contrast, the 57 Series caster:

That’s where TCO comes into play. The initial price tag is just one line on the spreadsheet—but ongoing costs? That’s where the real dollars live. |

Real-World Applications: Assembly Plants That Run Lean

We’ve seen this transformation across multiple major OEMs and Tier 1 automotive suppliers. Facilities that switch to the 57 Series report:

|

And because the 57 Series is engineered for standard bolt patterns and mounting options, switching is as simple as unscrewing the old—and bolting on the better. No retooling. No redesign. Just immediate results.

Here’s how the TCO math breaks down for a single caster over a 3-year period:

| Factor | Orange Caster | 57 Series |

| Initial Cost | $ | $$$ |

| Replacement Frequency | 2x/year | 0 |

| Maintenance Time | 2-3 hours/year | 0 |

| Downtime Impact | Medium to High | Low |

| Operator Ergonomics | Degraded over time | Maintained |

| Total Cost Over 3 Years | $$$$$ | $$$ |

Even with a higher upfront investment, the 57 Series pays for itself within the first year—and continues delivering value every day after.

At the heart of the 57 Series’ performance is the sealed precision ball bearing swivel section—a critical difference from the open single ball race design found in orange casters. Sealed bearings keep out dirt and grime and consistently perform across varied temperature and moisture conditions. They also eliminate the need for lubrication. In short, precision engineering leads to precision performance. And in a lean automotive facility, precision is everything.

The next time you order casters for your carts, dollies, or AGVs—ask yourself this: “Am I buying the cheapest caster… or the most cost-effective solution?”

The 57 Series is not just a caster—it’s an investment in uptime, safety, and long-term savings. Low-cost options like the orange CC Apex knockoffs may seem convenient, but they cost you every time you replace them, every time you maintain them, and every time they fail when you need them most.

Want to see the numbers for your own facility? We can help.

✅ Download a CAD model of the 57 Series

✅ Explore the 57 Series Caster Solutions →

✅ Contact our team at sales@casterconcepts.com