When it comes to industrial mobility, choosing the right wheels is crucial for efficiency, safety, and longevity. Polyurethane wheels have become a preferred choice in various industries due to their superior durability, high load capacity, and ability to protect floors from damage. Whether you’re looking for impact-resistant polyurethane or non-marking wheels for industrial use, these casters offer a versatile, long-lasting solution. This article explores how polyurethane wheels enhance performance in demanding environments.

When it comes to industrial mobility, choosing the right wheels is crucial for efficiency, safety, and longevity. Polyurethane wheels have become a preferred choice in various industries due to their superior durability, high load capacity, and ability to protect floors from damage. Whether you’re looking for impact-resistant polyurethane or non-marking wheels for industrial use, these casters offer a versatile, long-lasting solution. This article explores how polyurethane wheels enhance performance in demanding environments.

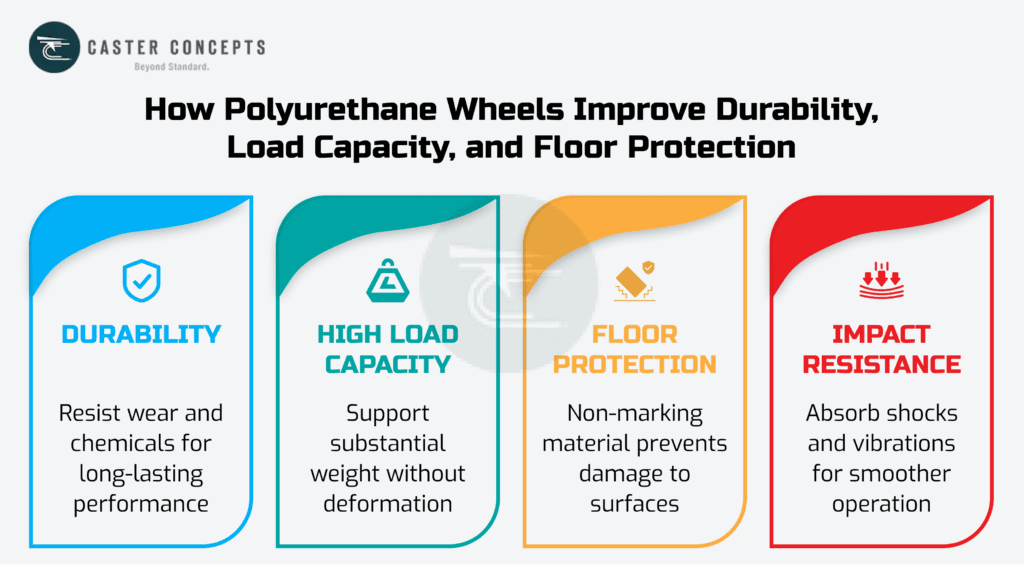

One of the standout features of polyurethane wheels is their exceptional durability. Unlike rubber or plastic wheels, durable polyurethane caster wheels resist wear and tear, even in harsh industrial settings. They maintain their shape and function over time, reducing the need for frequent replacements and minimizing downtime. Additionally, their resistance to chemicals, oil, and solvents ensures they remain effective in a wide range of applications, making them one of the best long-lasting industrial wheels available today.

Industrial environments require wheels that can handle heavy loads without compromising performance. High-load capacity polyurethane wheels provide the strength needed to support substantial weight while maintaining smooth and efficient movement. Unlike rubber wheels, which can compress under heavy loads, polyurethane wheels offer excellent load-bearing capabilities without deformation. This makes them ideal for applications such as manufacturing facilities, warehouses, and heavy equipment transport, where reliable weight distribution is essential.

A significant advantage of polyurethane wheels is their ability to protect flooring surfaces. In industrial settings, where equipment and carts move frequently, traditional wheels can cause scratches, scuffs, and other damage. Non-marking wheels for industrial use prevent these issues by offering a softer, more forgiving material that minimizes wear on concrete, tile, and other surfaces. This not only reduces maintenance costs but also creates a safer and more aesthetically pleasing work environment.

When transporting delicate or heavy loads, impact resistance is crucial to prevent damage to both the wheels and the transported items. Impact-resistant polyurethane wheels excel in absorbing shocks and vibrations, providing smoother operation even on uneven surfaces. The material’s inherent elasticity allows it to cushion impacts, reducing strain on both the wheel and the equipment it supports. This makes shock-absorbing polyurethane casters an excellent choice for industries that require the careful handling of goods, such as automotive manufacturing equipment transport.

Polyurethane wheels are a game-changer for industrial applications, offering unmatched durability, high load capacity, and exceptional floor protection. Their ability to resist impact, absorb shocks, and maintain performance over time makes them a superior choice compared to traditional wheel materials. Whether you’re seeking long-lasting industrial wheels or non-marking wheels for floor protection, polyurethane wheels provide a reliable and efficient solution for your mobility needs. Investing in high-quality polyurethane casters ensures smoother operations, reduced maintenance, and improved safety in any industrial setting. Caster Concepts is here to assist you with any caster concerns you might have. Let our experts help you pick the right wheel for your operations. Contact us today!