Choosing the right casters for your application can significantly impact efficiency, safety, and equipment longevity. When it comes to industrial and heavy-duty applications, selecting between spring loaded casters and standard casters is crucial. Understanding the difference between spring-loaded and rigid casters can help you determine which is best suited for your needs.

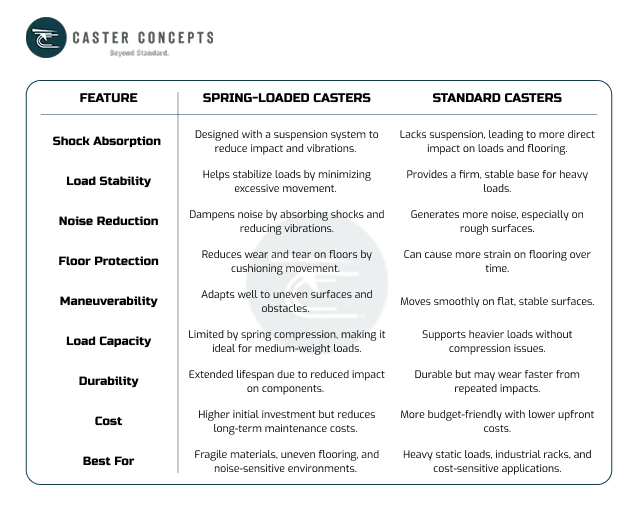

Spring loaded casters are designed with an integrated suspension system that absorbs shocks and reduces vibrations when moving heavy loads. These casters feature a spring mechanism that compresses under pressure, helping to mitigate impact forces and providing a smoother ride over uneven surfaces. Their key features include shock absorption to protect both the load and flooring, load stabilization that minimizes excessive vibrations, noise reduction for quieter operations, and extended equipment life by reducing shock and vibration. By cushioning movement, these casters help prevent damage to fragile materials, reduce noise levels in industrial environments, and prolong the lifespan of both the caster and the transported equipment.

are designed with an integrated suspension system that absorbs shocks and reduces vibrations when moving heavy loads. These casters feature a spring mechanism that compresses under pressure, helping to mitigate impact forces and providing a smoother ride over uneven surfaces. Their key features include shock absorption to protect both the load and flooring, load stabilization that minimizes excessive vibrations, noise reduction for quieter operations, and extended equipment life by reducing shock and vibration. By cushioning movement, these casters help prevent damage to fragile materials, reduce noise levels in industrial environments, and prolong the lifespan of both the caster and the transported equipment.

Standard casters, also known as rigid casters, are simple rolling mechanisms without built-in suspension systems. They offer a sturdy, cost-effective solution for applications that require straightforward mobility without additional cushioning. These casters are known for their high load capacity as they can support significant weight without the risk of spring compression affecting stability. Their simple design, with fewer components, results in lower maintenance and higher durability in basic transport applications. Additionally, standard casters maintain firm contact with the floor, providing precise maneuvering, and are more cost-effective compared to spring loaded casters, making them an economical choice for many industries.

Spring casters are the ideal choice for applications that require shock absorption, noise reduction, and protection against impact damage than the rigid casters. Common uses include:

For applications that require durability, high load-bearing capacity, and cost-effectiveness, rigid casters are the preferred choice. They are best suited for:

For applications that require durability, high load-bearing capacity, and cost-effectiveness, rigid casters are the preferred choice. They are best suited for:

To determine which caster type is best for your needs, consider the following:

Selecting the right caster type is essential for optimizing efficiency, safety, and cost-effectiveness in industrial applications. Understanding the difference between spring-loaded and rigid casters ensures you make the best choice for your specific application needs. Whether you prioritize load stabilization with spring casters or need a high-capacity solution with traditional casters, Caster Concepts provides durable and high-performance solutions tailored to your industry’s demands. Contact us today!