In industrial environments, the constant movement of equipment and materials can often lead to disruptive noise, damaging vibrations, and even wear and tear on machinery. These issues can not only affect the health and well-being of workers but also result in costly repairs and downtime for equipment. One highly effective solution to these problems is the use of spring-loaded casters. These casters are designed to absorb shock, reduce noise, and protect equipment from potential damage, making them an essential component in material handling and transport systems.

Spring-loaded casters are wheels equipped with a spring suspension system designed to absorb shock and vibration. They are commonly used in environments where heavy loads or equipment are subjected to rough surfaces and high-impact transport. The spring mechanism helps cushion the load, minimizing the impact on the equipment being moved and reducing the potential for noise and vibrations.

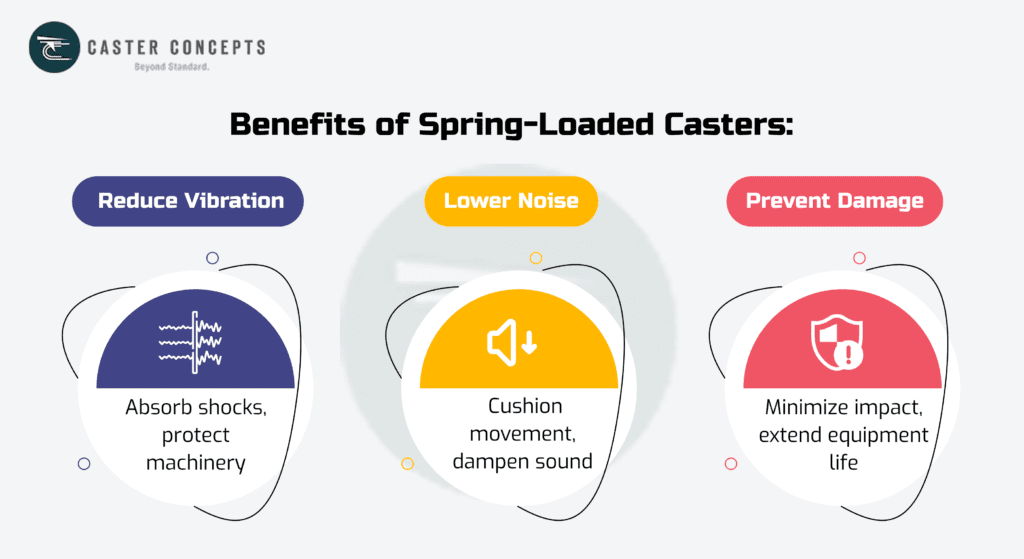

Vibration is inherent in many industrial environments, particularly in factories and warehouses where large, heavy loads are regularly moved. Vibrations can cause damage to machinery, affect the quality of products, and lead to an uncomfortable working environment. Spring-loaded casters help mitigate this problem by absorbing the shocks generated during movement.

The spring suspension mechanism in these casters acts as a buffer, distributing the force from uneven or bumpy surfaces and preventing it from being transferred directly to the equipment. This helps to reduce the frequency and intensity of vibrations, creating a smoother and quieter transport process. As a result, spring-loaded casters enhance the operational efficiency of the workplace. They also protect sensitive equipment and machinery from the harmful effects of excessive vibration.

Noise pollution is another common issue in industrial environments. The constant sound of metal on concrete, coupled with machinery running at full speed, can contribute to a loud, disruptive atmosphere. Over time, excessive noise can negatively impact worker concentration, productivity, and even long-term health.

Spring-loaded casters are particularly effective in reducing noise because they provide a cushioning effect. Spring suspension absorbs and dampens the sound generated when equipment is in motion. This is especially beneficial in factories and warehouses where carts, racks, and other equipment are frequently moved across hard surfaces. By reducing the noise generated during these movements, spring-loaded casters contribute to a quieter and safer working environment.

93 Series Spring Loaded Caster

In addition to reducing noise and vibration, spring-loaded casters also play a vital role in preventing equipment damage. Without shock-absorbing casters, equipment is more likely to experience impact-related damage when moving. Hard bumps, abrupt stops, and uneven surfaces can cause internal components to shift or become misaligned, leading to costly repairs and downtime.

Spring suspension wheels for industrial use help to cushion the load, reducing the impact of sudden jolts or bumps. This minimizes the risk of damage to the equipment and the surfaces it moves across. Businesses can extend the lifespan of their equipment by protecting valuable machinery from these harmful forces. This also helps reduce repair costs and eliminates the need for frequent replacements.

Spring-loaded casters play an essential role in reducing noise, vibration, and equipment damage in industrial and warehouse settings. At Caster Concepts, we specialize in providing high-quality spring-loaded casters designed for durability, performance, and noise reduction. Let us help you improve the efficiency and longevity of your equipment with our innovative caster solutions. Contact us today!